How We Build Better than New GSE®

The RCL Process

Quality Built Into Every Step

We strip old units to their bare frame and rebuild them through our meticulous remanufacturing process. This allows our customers to place a true "zero-time" unit into service, achieving unmatched reliability for up to 50% less than the cost of new equipment.

Step-By-Step

The "Zero-Time" Remanufacturing Process

1

Disassembly

The unit is received, with any defects noted and options to be added. The unit is then taken apart, with parts organized to the unit.

Learn More

2

Blast

All surfaces are media blasted to bare steel, ready for fabrication.

Learn More

3

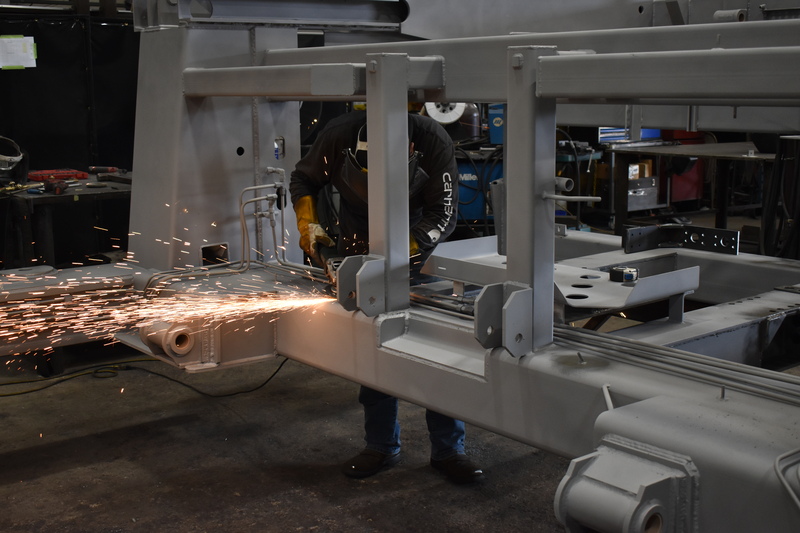

Fabrication

Our fabrication team examines and repairs any damaged weldments and structural components. Any components damaged beyond repair are replaced with new.

Learn More

4

Paint

The frame and structural members go through the painting process to ensure all mating surfaces are painted before being assembled.

Learn More

5

Electrical

Each unit is upgraded with a completely new electrical system, built around a modern CAN bus network that allows for easier diagnostics and better reliability.

Learn More

6

Power Plant

The customer's choice of either a Lithium-ion or diesel power plant is installed in the unit's motor compartment.

Learn More

7

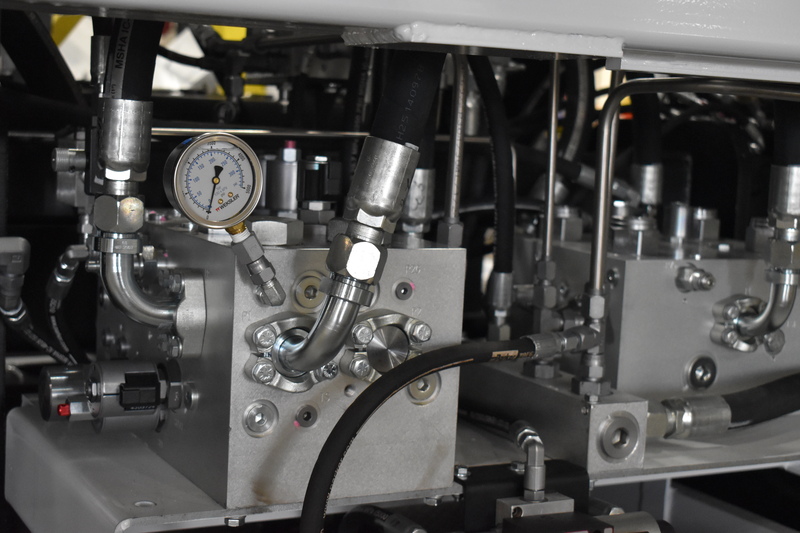

Hydraulics

New, re-engineered hydraulic manifolds are installed for improved efficiency and simplified troubleshooting. Parker Tough Cover hoses are our standard to ensure maximum durability.

Learn More

8

Assembly

Our assembly process utilizes a specialized "pod" system for precision and quality. Expertly-trained technicians build components in dedicated areas before final integration onto the unit.

Learn More

9

Quality Control

Units go through our extensive quality control process and are operated for a minimum of 12 hours simulating operating conditions. Completed units are prepared for shipping.

Learn More

10

Commissioning

The unit is delivered to our customer, with an RCL technician meeting the unit onsite to re-assemble and test all functions.

Learn More